Legacy Memorials is your trusted source for custom designed stone monuments, markers and headstones.

Serving the Vernon & Kelowna region for over 30 years, we also offer on-site repair and restoration services throughout British Columbia.

Legacy Memorials is your trusted source for custom designed stone monuments, markers and headstones. Serving the Vernon & Kelowna region for over 30 years, we also offer on-site repair and restoration services throughout British Columbia.

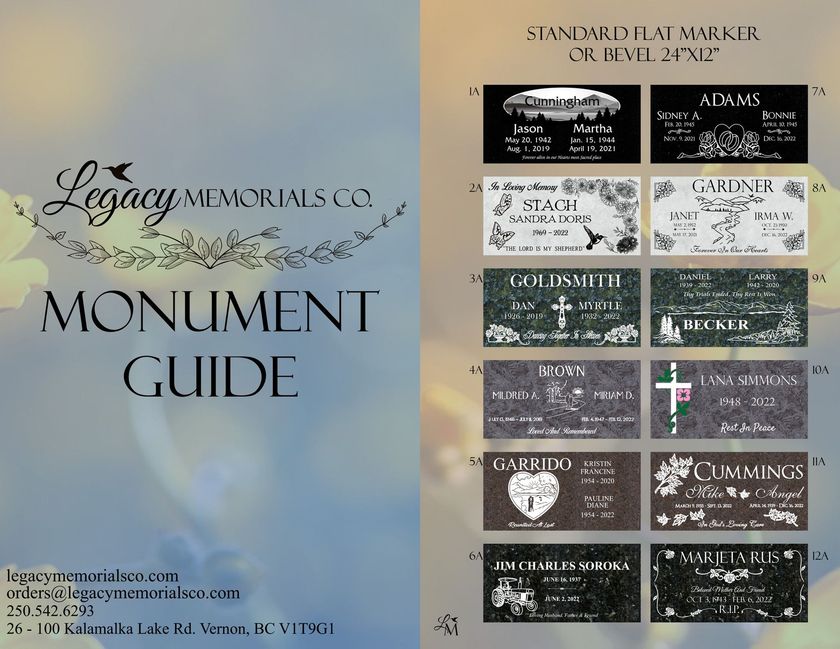

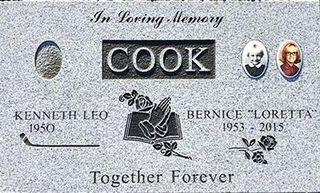

Memorial Types & Styles

Stone Monuments & Markers

We specialize in crafting custom monuments, headstones, and markers that serve as timeless tributes. Our bespoke designs ensure that each piece is as unique as the life it commemorates.

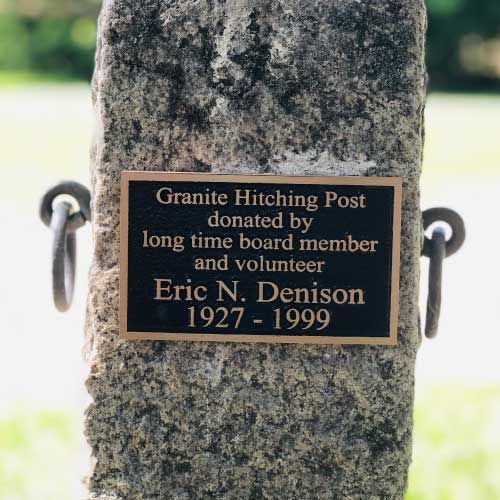

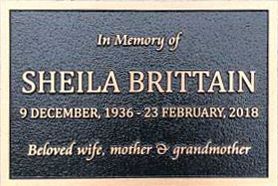

Bronze Plaques & Plates

Discover the art of remembrance through our custom cast bronze and engraved metal plaques. We also craft name bars and plates suited for cremation walls and memorial benches.

On-Site Services

Legacy Memorials is the only memorials company that offers on-site headstone, marker and monument restoration, repair and addition services throughout British Columbia. Our skilled artisans travel across the province to ensure that every memorial—old or new—receives the care and attention it deserves.

Restorations & Repairs

Preserve the dignity and appearance of existing memorials with our specialized on-site restoration service.

Utilizing a custom sandblasting technique, our skilled artisans meticulously match the existing text in both size and font before applying a protective mask and initiating the sandblasting process. This meticulous approach allows us to revive the look of worn or weathered headstones and markers, breathing new life into these lasting tributes to your loved ones.

Completing an on-site headstone restoration

Adding name & date to a headstone memorial

Name & Date Additions

Deepen the narrative of your cherished one's memorial through this specialized service. Whether incorporating final resting dates, introducing new names to the monument, or enriching the stone with unique designs or heartfelt quotations, our process ensures a dignified and smooth transition for these updates. For your peace of mind, we offer preliminary visualizations to help you envision how the new elements will harmonize with the existing memorial.

Why Choose Us?

Our in-house and on-site sandblasting services, paired with an extensive selection of granite stones and bronze plaques and plates, can help make your original and creative memorial ideas become a reality - quickly and easily.

Industry Experts

Fast Service

Competitive Pricing

Want a closer look at our work?

Our PDF brochure shows some examples of our custom monuments and headstones. It's a quick and easy way to get inspired for your own memorial project.

Custom Memorial Creation Process

Custom Memorial

Creation Process

Consultation

We'll help guide you through the type and size of monuments that are allowed in the cemetery in your region. This phase is also where you'll be choosing the colour of the stone and discussing design elements that reflect your personal preferences.

Design

To get the design just right, we'll need the names, dates, and any images you want on the stone. We'll then send you 2-3 digital proofs with different fonts and images for your review. You can choose elements from each, and up to three sets of changes are included in the initial cost. We require written approval of the final design to move into production.

Production

Once design approval is received, the stone goes into production, which can take a few weeks if the stone is in stock. If the stone is not in stock, the production timeline can extend up to six months due to industry-wide delays.

Installation

After production, your stone is either delivered to the specified cemetery or another designated location. Photo proof of the installed or delivered stone will be provided to you for confirmation.

Our Story

"It all started when my mom passed away, and I wanted to create a beautiful memorial that incorporated the things that meant a lot to her. With my background in graphic design, I created a custom design through my art software and sought someone who could transfer it onto a gravestone. I went to the local monument shop at the time, and showed them the design, only to be laughed at by the owner, who said it was impossible..."

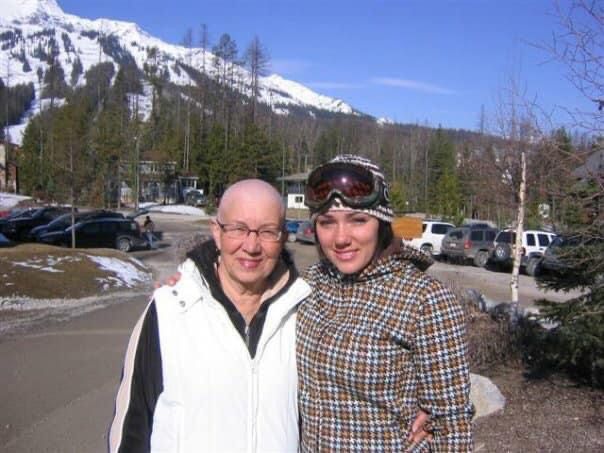

Legacy Memorials owner Kimberley Shippam with her mom, Elizabeth

Get started with a free quote for your custom memorial needs.

Professionalism at its best! The team at Legacy Memorials are friendly, honest and extremely talented. If you are looking for a world class custom design for a memorial stone, look no further. Kim and her team will exceed your expectations!!

- BL

Contact Us

Unit 26 - 100 Kalamalka Lake Rd

Vernon, BC V1T 9G1

(in the Alpine Centre)

Mon-Fri: 8:30am-4:30pm

All Rights Reserved | Legacy Memorials

Website by Colibrico